Overview

Field of interest of the company founders since early 1980 was the development and tests of the automatic control system for hovercraft, type of the ships with much faster dynamics comparing to majority of the offshore vessels.

This experience and fundamental knowledge of the subject was the base for the successful lunch of the first system on board of “Candy Pioneer” in February 2000.

Around 800 systems now serve our customers on board of the ships in major oil and gas offshore development areas.

Unique algorithms help us to keep the position of the vessels with fast dynamics, lightweight and shallow draft — fast crew boats and jack-up rigs vessels, or in cases when fast reaction from the system is required.

In 2002 we have delivered dynamic positing system for the first water jet driven fast crew boat in the world. Since than we deliver around 150 systems to boats with different propulsion configurations — from simple in build and operation fixed pitch propellers and to recently developed and delivered hybrid driven ones.

Please use menu on the right to get more details on this product.

Yevgeniy NETUK | Master of PSV “Bourbon Liberty 152” | BOURBON OFFSHORE GREENMAR

Opinion after software upgrade of DP Control System:

“Actually, this updated software is perfect!

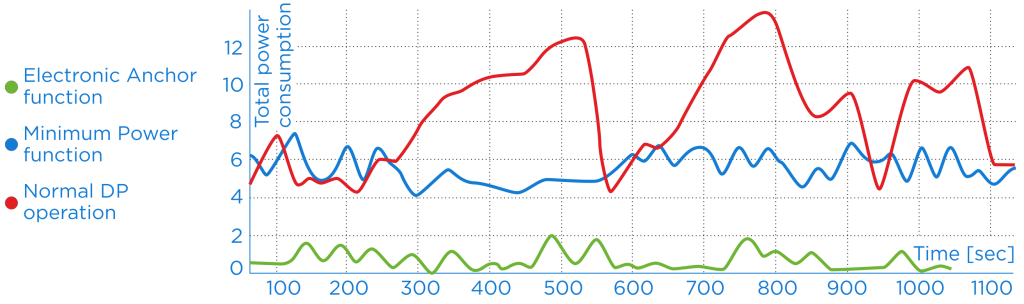

There are new Min Power Heading and Hold Area modes when vessel is on standby outside of installation’s 500m zone. When these modes are ON, diesel generator power consumption is minimum in compare to previous Dynamic Positioning software version, 1 x Bow thrusters (BT) is stopped and ready for auto start on demand by DP system. No more noise from thrusters high RPMs. Vessel is like weathervaning and following environmental forces within predefined by DP operator sector.

Full DP Mode: Bow thruster Group Bias – Excellent function. Bow thruster are working in opposite direction to avoid frequent clutching in and thus saving bow thrusters contactors. Same, one Bow thruster is running and in case the system demands more than 25% of thruster force, then 2nd bow thruster is being started and working in required direction.”